-

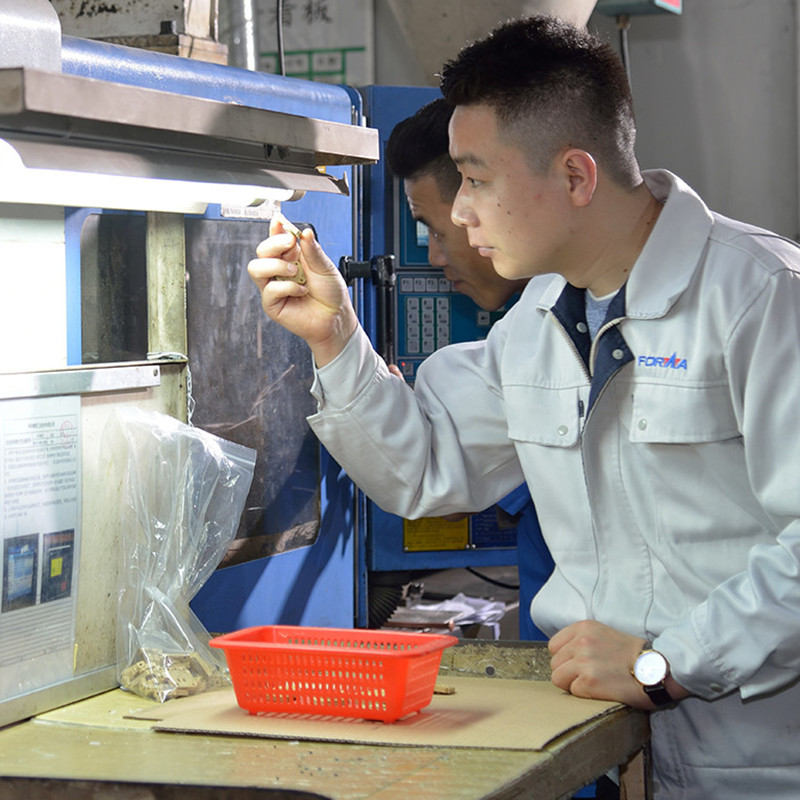

About Us

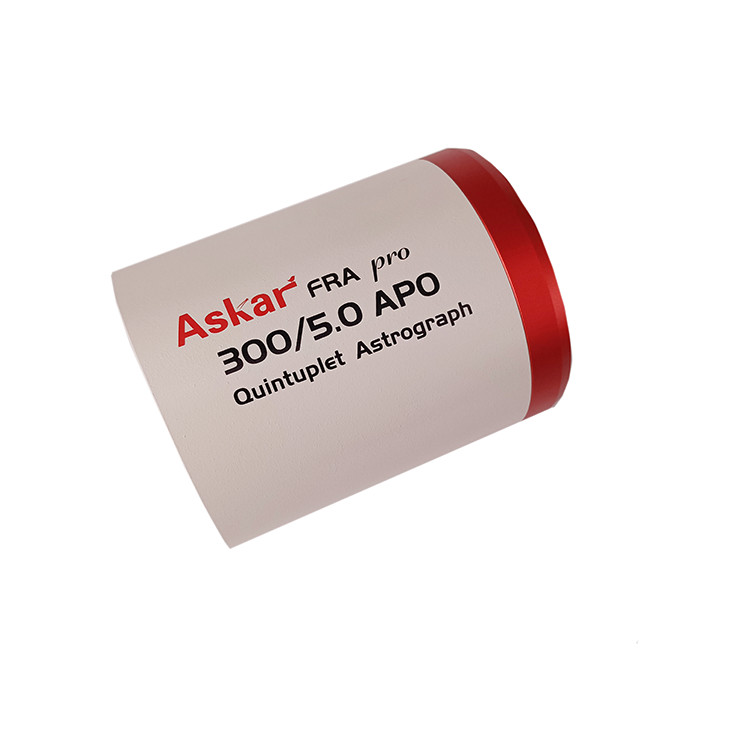

- Plastic Mold

-

Plastic Molding Manufacturing

Auto Part Molding Manufacturing Plastic Gear Molding Manufacturing Electronic Product Molding Manufacturing Medical Device Part Molding Manufacturing Overmolding Part Molding Manufacturing Transparent Part Molding Manufacturing Sport Part Molding Manufacturing Insert Molding Part Molding Manufacturing

- Service

-

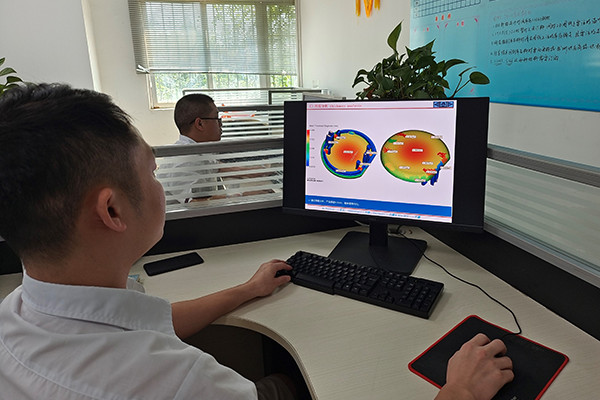

Company Capabilities

- News

-

Contact